2 Flute Carbide Ball Nose End Mill HRC55 High Speed Milling Cutter

High Speed Milling Cutter HRC55 Carbide 2 Flute Ball Nose End Mills

Features of ball nose end mill

1. Wide machining range and large chip removal space:

This ball nose milling cutter mainly focuses on profiling, semi-finishing and finishing, and it is recommended to cut materials within HRC55 degrees;

2. Long service life:

It can directly carry out high-speed rough machining to fine machining of heat-treated materials below 55 degrees, reduce the number of tool changes, advance the machining rate of the machine tool and save the manufacturing time, mainly cutting surface milling/short side milling;

3. Large chip removal groove, high hardness and wear resistance:

The design of large chip removal groove and large spiral chip removal groove at the cutting edge, the chip removal is not accumulated, the surface finish is good, and the processing design of the burr supporting double-edge belt.

Milling Parameters of ball nose end mill

| HRC55 Carbide Ball Nose End Mill | Tool length | fz&v |

| Short | 1 |

| Long1 | 0.9 |

| Overlength | 0.8 |

| Speciality | 0.6 |

| Type | Material | Strength

N/mm²

Hardness

HRC | Cooling |

| Air | Dry cutting | Lubricating fluid |

| P | PI | P1.1 | Non alloy structural steel, free cutting structural steel, carburized steel and quenched and tempered steel | <700 | √ | √ | √ |

| P1.2 | quenched and tempered steel | <1200 | √ | √ | √ |

| P2 | P2.1 | Alloyed nitrided steel, carburized steel and quenched and tempered steel | <900 | √ | √ | √ |

| P2.2 | Tool steel, bearing steel, spring steel and high-speed steel | <1400 | √ | | √ |

| P3 | P3.1 | Tool steel, bearing steel, spring steel and high-speed steel | <900 | √ | √ | √ |

| P3.2 | Tool steel, bearing steel, spring steel and high-speed steel | <1500 | √ | | √ |

| M | M1 | M1.1 | austenitic stainless steel | <700 | √ | | √ |

| M1.2 | Ferritic/austenitic (bicrystal) stainless steel | <1000 | | | √ |

| M2 | M2.1 | Austenitic stainless cast steel | <700 | √ | | √ |

| M3 | M3.1 | Ferritic/austenitic (bicrystal) stainless cast steel | <1000 | | | √ |

| K | K1 | K1.1 | Flake graphite cast iron (gray cast iron), GJL | <300 | √ | √ | √ |

| K2 | K2.1 | Ductile iron, GJS | <500 | √ | √ | √ |

| K2.2 | Ductile iron, GJS | 500-800 | √ | √ | √ |

| K2.3 | Ductile iron, GJS | >800 | √ | √ | √ |

| K3 | K3.1 | Vermicular graphite cast iron, GJV; Malleable cast iron, GJM | <500 | √ | √ | √ |

| K3.2 | Vermicular graphite cast iron, GJV; Malleable cast iron, GJM | >500 | √ | √ | √ |

| Slotting |

Vc

(m/min) | fz(mm/tooth) |

| Diameter |

| 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| 112 | 0.01 | 0.018 | 0.026 | 0.034 | 0.041 | 0.048 | 0.054 | 0.06 | 0.065 | 0.069 |

| 92 | 0.01 | 0.017 | 0.025 | 0.032 | 0.038 | 0.045 | 0.0505 | 0.056 | 0.061 | 0.065 |

| 100 | 0.01 | 0.018 | 0.026 | 0.034 | 0.041 | 0.048 | 0.054 | 0.06 | 0.065 | 0.069 |

| 72 | 0.009 | 0.015 | 0.022 | 0.028 | 0.034 | 0.04 | 0.045 | 0.05 | 0.054 | 0.058 |

| 64 | 0.01 | 0.018 | 0.025 | 0.032 | 0.039 | 0.045 | 0.051 | 0.057 | 0.062 | 0.066 |

| 56 | 0.009 | 0.016 | 0.023 | 0.029 | 0.036 | 0.041 | 0.0465 | 0.052 | 0.056 | 0.06 |

| 44 | 0.007 | 0.012 | 0.018 | 0.023 | 0.027 | 0.032 | 0.036 | 0.04 | 0.043 | 0.046 |

| 68 | 0.01 | 0.018 | 0.025 | 0.033 | 0.04 | 0.046 | 0.052 | 0.058 | 0.063 | 0.067 |

| 44 | 0.005 | 0.009 | 0.012 | 0.016 | 0.019 | 0.022 | 0.025 | 0.028 | 0.030 | 0.032 |

| 32 | 0.006 | 0.011 | 0.015 | 0.02 | 0.024 | 0.028 | 0.0315 | 0.035 | 0.0375 | 0.04 |

| 28 | 0.005 | 0.009 | 0.013 | 0.016 | 0.02 | 0.023 | 0.031 | 0.039 | 0.036 | 0.033 |

| 32 | 0.007 | 0.012 | 0.017 | 0.021 | 0.026 | 0.03 | 0.034 | 0.038 | 0.041 | 0.044 |

| 32 | 0.005 | 0.009 | 0.013 | 0.017 | 0.021 | 0.024 | 0.027 | 0.03 | 0.0325 | 0.035 |

| 120 | 0.017 | 0.031 | 0.044 | 0.056 | 0.068 | 0.08 | 0.09 | 0.1 | 0.05575 | 0.0115 |

| 112 | 0.015 | 0.026 | 0.037 | 0.048 | 0.058 | 0.068 | 0.0765 | 0.085 | 0.0915 | 0.098 |

| 92 | 0.012 | 0.022 | 0.031 | 0.039 | 0.048 | 0.056 | 0.063 | 0.07 | 0.0755 | 0.081 |

| 52 | 0.007 | 0.012 | 0.018 | 0.023 | 0.027 | 0.032 | 0.036 | 0.04 | 0.043 | 0.046 |

| 80 | 0.012 | 0.022 | 0.031 | 0.039 | 0.048 | 0.056 | 0.063 | 0.07 | 0.0755 | 0.081 |

| 76 | 0.01 | 0.018 | 0.026 | 0.034 | 0.041 | 0.048 | 0.054 | 0.06 | 0.0645 | 0.069 |

| Roughing |

Vc

(m/min) | fz(mm/tooth) |

| Diameter |

| 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| 228 | 0.018 | 0.031 | 0.045 | 0.057 | 0.070 | 0.081 | 0.091 | 0.101 | 0.110 | 0.118 |

| 208 | 0.017 | 0.029 | 0.042 | 0.054 | 0.065 | 0.071 | 0.083 | 0.095 | 0.103 | 0.11 |

| 184 | 0.018 | 0.031 | 0.045 | 0.057 | 0.070 | 0.081 | 0.091 | 0.101 | 0.110 | 0.118 |

| 144 | 0.015 | 0.026 | 0.037 | 0.048 | 0.058 | 0.068 | 0.077 | 0.085 | 0.092 | 0.098 |

| 132 | 0.017 | 0.03 | 0.042 | 0.054 | 0.066 | 0.077 | 0.087 | 0.096 | 0.104 | 0.112 |

| 112 | 0.015 | 0.027 | 0.039 | 0.05 | 0.060 | 0.07 | 0.079 | 0.088 | 0.095 | 0.102 |

| 92 | 0.012 | 0.021 | 0.03 | 0.038 | 0.046 | 0.054 | 0.061 | 0.068 | 0.073 | 0.078 |

| 140 | 0.017 | 0.03 | 0.043 | 0.055 | 0.067 | 0.078 | 0.088 | 0.098 | 0.106 | 0.114 |

| 92 | 0.008 | 0.015 | 0.021 | 0.027 | 0.032 | 0.038 | 0.043 | 0.047 | 0.051 | 0.055 |

| 60 | 0.011 | 0.018 | 0.026 | 0.033 | 0.041 | 0.047 | 0.053 | 0.059 | 0.064 | 0.069 |

| 56 | 0.009 | 0.015 | 0.022 | 0.028 | 0.034 | 0.039 | 0.044 | 0.049 | 0.053 | 0.057 |

| 68 | 0.011 | 0.02 | 0.028 | 0.036 | 0.044 | 0.051 | 0.0575 | 0.064 | 0.069 | 0.074 |

| 60 | 0.009 | 0.016 | 0.022 | 0.029 | 0.035 | 0.041 | 0.046 | 0.051 | 0.055 | 0.059 |

| 248 | 0.03 | 0.052 | 0.074 | 0.096 | 0.0116 | 0.135 | 0.152 | 0.169 | 0.1825 | 0.196 |

| 228 | 0.025 | 0.044 | 0.063 | 0.081 | 0.099 | 0.115 | 0.1295 | 0.144 | 0.155 | 0.166 |

| 184 | 0.021 | 0.037 | 0.052 | 0.067 | 0.081 | 0.095 | 0.1065 | 0.118 | 0.1275 | 0.137 |

| 104 | 0.012 | 0.021 | 0.03 | 0.038 | 0.046 | 0.054 | 0.061 | 0.068 | 0.073 | 0.078 |

| 164 | 0.021 | 0.037 | 0.052 | 0.067 | 0.081 | 0.095 | 0.1065 | 0.118 | 0.1275 | 0.137 |

| 156 | 0.018 | 0.031 | 0.045 | 0.057 | 0.07 | 0.081 | 0.091 | 0.101 | 0.1095 | 0.118 |

| Finish |

Vc

(m/min) | fz(mm/tooth) |

| Diameter |

| 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| 332 | 0.028 | 0.05 | 0.07 | 0.091 | 0.11 | 0.128 | 0.144 | 0.16 | 0.173 | 0.186 |

| 272 | 0.026 | 0.046 | 0.066 | 0.085 | 0.103 | 0.12 | 0.135 | 0.15 | 0.162 | 0.173 |

| 304 | 0.028 | 0.05 | 0.07 | 0.091 | 0.11 | 0.128 | 0.144 | 0.16 | 0.173 | 0.186 |

| 212 | 0.023 | 0.041 | 0.059 | 0.076 | 0.092 | 0.107 | 0.121 | 0.134 | 0.145 | 0.155 |

| 196 | 0.027 | 0.047 | 0.067 | 0.086 | 0.104 | 0.122 | 0.137 | 0.152 | 0.165 | 0.177 |

| 168 | 0.024 | 0.043 | 0.061 | 0.079 | 0.095 | 0.111 | 0.125 | 0.139 | 0.150 | 0.161 |

| 136 | 0.019 | 0.033 | 0.047 | 0.06 | 0.073 | 0.085 | 0.096 | 0.107 | 0.116 | 0.124 |

| 204 | 0.027 | 0.048 | 0.068 | 0.088 | 0.106 | 0.124 | 0.140 | 0.155 | 0.168 | 0.18 |

| 136 | 0.013 | 0.023 | 0.033 | 0.042 | 0.051 | 0.06 | 0.068 | 0.075 | 0.081 | 0.087 |

| 92 | 0.016 | 0.029 | 0.041 | 0.053 | 0.064 | 0.075 | 0.0845 | 0.094 | 0.101 | 0.108 |

| 84 | 0.014 | 0.024 | 0.034 | 0.044 | 0.053 | 0.062 | 0.0695 | 0.077 | 0.0835 | 0.09 |

| 100 | 0.018 | 0.031 | 0.045 | 0.057 | 0.07 | 0.081 | 0.0915 | 0.102 | 0.11 | 0.118 |

| 92 | 0.014 | 0.025 | 0.035 | 0.045 | 0.055 | 0.064 | 0.072 | 0.08 | 0.0865 | 0.093 |

| 364 | 0.047 | 0.083 | 0.117 | 0.151 | 0.183 | 0.214 | 0.2405 | 0.267 | 0.149 | 0.031 |

| 332 | 0.04 | 0.07 | 0.1 | 0.128 | 0.156 | 0.182 | 0.2045 | 0.227 | 0.245 | 0.263 |

| 272 | 0.033 | 0.058 | 0.082 | 0.106 | 0.128 | 0.149 | 0.168 | 0.187 | 0.202 | 0.217 |

| 152 | 0.019 | 0.033 | 0.047 | 0.06 | 0.073 | 0.085 | 0.096 | 0.107 | 0.1155 | 0.124 |

| 240 | 0.033 | 0.058 | 0.082 | 0.106 | 0.128 | 0.149 | 0.168 | 0.187 | 0.202 | 0.217 |

| 228 | 0.028 | 0.05 | 0.07 | 0.091 | 0.011 | 0.128 | 0.144 | 0.16 | 0.173 | 0.186 |

Note

- If the following carbide ball nose end mill cannot meet your requirements, we support OEM customized production. The diameter of 0.2mm to 25mm, the total length of 50mm to 200mm, 4F, 5F, 6F, 8F and logo can be customized, including inch size end milling cutter. Please contact us to select or customize non-standard carbide end mill according to your needs.

| Specification | Flute Dia(D) | Flute Length (C) | Shank Dia(D) | Overall Length(L) |

| Φ4*10*d4*50L | 4 | 10 | 4 | 50 |

| Φ5*13*d5*50L | 5 | 13 | 5 | 50 |

| Φ6*15*d6*50L | 6 | 15 | 6 | 50 |

| Φ8*20*d8*60L | 8 | 20 | 8 | 60 |

| Φ10*25*d10*75L | 10 | 25 | 10 | 75 |

| Φ12*30*d12*75L | 12 | 30 | 12 | 75 |

| Φ8*35*d8*100L | 8 | 35 | 8 | 100 |

| Φ10*40*d10*100L | 10 | 40 | 10 | 100 |

| Φ12*45*d12*100L | 12 | 45 | 12 | 100 |

| Φ14*45*d14*100L | 14 | 45 | 14 | 100 |

| Φ16*45*d16*100L | 16 | 45 | 16 | 100 |

| Φ18*45*d18*100L | 18 | 45 | 18 | 100 |

| Φ20*45*d20*100L | 20 | 45 | 20 | 100 |

Instructions of ball nose end mill

1. Before using the carbide ball nose end mill, please measure the tool deflection. If the tool deflection accuracy exceeds 0.01mm, please correct it before cutting.

2. The shorter the carbide extends out of the collet, the better. If the tool extends out longer, reduce the speed, feed speed or cutting amount.

3. In case of abnormal vibration or sound during cutting, please reduce the speed and cutting amount until the situation is improved.

4. Spray type and air jet type are preferred for steel cooling, which can improve the use effect of carbide ball nose end mill.

5. Note: Not suitable for low speed machines such as rotary table and electric hand drill.

Advantages of ball nose end mill

- Product quality is guaranteed

15 technical R&D personnel;

Imported five-axis machine tool;

Imported testing equipment;

The qualified rate of finished products is 99.9%

- 360 ° comprehensive service

Various after-sales protection policies;

Timely delivery of goods;

Provide props design support

- Strong production capacity

11000 square meters of factory;

240 professional equipment;

30 production workers;

Multi-factory cooperation designated unit

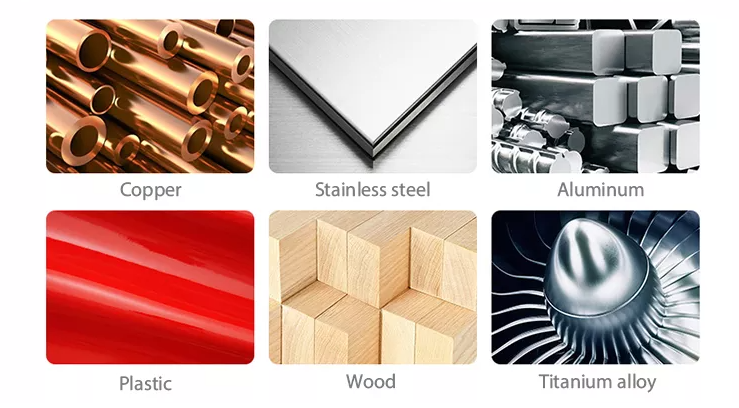

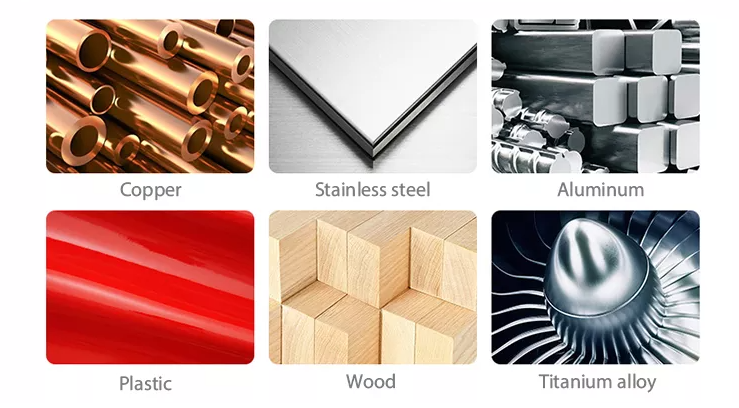

Applications of ball nose end mill

Pre-hardened Steel, stainless steel, Die steel, steel plate, Heat-resistant steel,pipe, copper and aluminum, cast iron, Nonferrous Metal, Wood, Plastic,FRP and so on. General-purpose operation slotting, rilling, profiling.

1) Are you manufacturer? Do you have factory?

We are professional manufacturer, have more than 12 years experience in this field.

2) When can I get the price?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

3) Is free shipping possible?

We don't offer free shipping service, but we will give you some discount if you buy large quantity products. And we have cooperation Express Companies, can offer you the best price of shipping cost.

4) How long is your delivery time?

Generally it is 5-10 days if the goods are in stock, or it is 15-20 days if the goods are not in stock, it is according to quantity.

5) Whats your MOQ?

We welcome your sample order to test our quality, we believe that you will find that we are the right supplier you are looking for. So no MOQ.