Quick Detail OF Micro Diameter Ball End Mill

- Imported tungsten steel bars from Germany

- High quality TiAlN coating

- 35 ° spiral angle design

- Tank bottom precision grinding process

- Large core diameter design

- Handle chamfer design

Description OF Micro Diameter Ball End Mill

The HRC65 micro diameter ball end milling cutter is made by

selecting materials and precision grinding. It is manufactured

using Anka machine tools and German processes to ensure the outer

diameter size and accuracy of the micro diameter milling cutter. At

the same time, it also has excellent characteristics such as high

hardness and good wear resistance. It can perform precision

machining and semi precision machining on heat treated materials

below 65 degrees Celsius; Adopting imported first-class precision

machine tools to grind unique spiral blade angles, sharp and

wear-resistant, high-speed cutting, less prone to tool breakage,

reduced tool replacement times, improved machine tool movement, and

improved milling efficiency; Imported passivation equipment. Fine

and blunt sanding enhances the corrosion resistance and wear

resistance of the cutting tool, ensuring smooth and burr free

cutting, and prolonging the service life of the milling cutter.

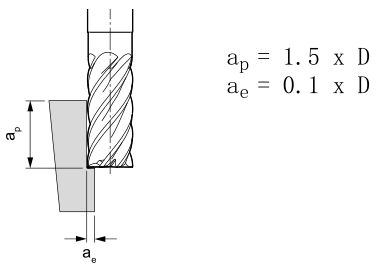

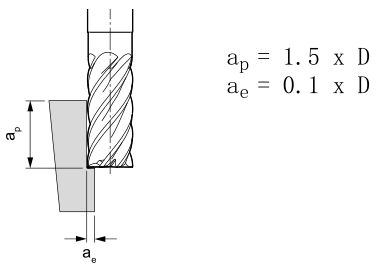

Milling parameters OF Micro Diameter Ball End Mill

HRC55 Carbide Micro Diameter Square End Mill

| Tool length | fz&v |

| Short | 1 |

| Long1 | 0.9 |

| Overlength | 0.8 |

| Speciality | 0.6 |

| Type | Material | Strength N/mm²

Hardness HRC | Cooling |

| Air | Dry cutting | Lubricating fluid |

| P | PI | P1.1 | Non alloy structural steel, free cutting structural steel,

carburized steel and quenched and tempered steel | <700 | √ | √ | √ |

| P1.2 | quenched and tempered steel | <1200 | √ | √ | √ |

| P2 | P2.1 | Alloyed nitrided steel, carburized steel and quenched and tempered

steel | <900 | √ | √ | √ |

| P2.2 | Tool steel, bearing steel, spring steel and high-speed steel | <1400 | √ | | √ |

| P3 | P3.1 | Tool steel, bearing steel, spring steel and high-speed steel | <900 | √ | √ | √ |

| P3.2 | Tool steel, bearing steel, spring steel and high-speed steel | <1500 | √ | | √ |

| Sloting |

Vc

(m/min) | fz(mm/Tooth) |

| Diameter |

| 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

| 112 | 0.01 | 0.018 | 0.026 | 0.034 | 0.041 | 0.048 | 0.06 | 0.069 |

| 92 | 0.01 | 0.017 | 0.025 | 0.032 | 0.038 | 0.045 | 0.056 | 0.065 |

| 100 | 0.01 | 0.018 | 0.026 | 0.034 | 0.041 | 0.048 | 0.06 | 0.069 |

| 72 | 0.009 | 0.015 | 0.022 | 0.028 | 0.034 | 0.04 | 0.05 | 0.058 |

| 64 | 0.01 | 0.018 | 0.025 | 0.032 | 0.039 | 0.045 | 0.057 | 0.066 |

| 56 | 0.009 | 0.016 | 0.023 | 0.029 | 0.036 | 0.041 | 0.052 | 0.06 |

| Roughing |

Vc

(m/min) | fz(mm/Tooth) |

| Diameter |

| 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

| 228 | 0.018 | 0.031 | 0.045 | 0.057 | 0.070 | 0.081 | 0.101 | 0.118 |

| 208 | 0.017 | 0.029 | 0.042 | 0.054 | 0.065 | 0.071 | 0.095 | 0.11 |

| 184 | 0.018 | 0.031 | 0.045 | 0.057 | 0.070 | 0.081 | 0.101 | 0.118 |

| 144 | 0.015 | 0.026 | 0.037 | 0.048 | 0.058 | 0.068 | 0.085 | 0.098 |

| 132 | 0.017 | 0.03 | 0.042 | 0.054 | 0.066 | 0.077 | 0.096 | 0.112 |

| 112 | 0.015 | 0.027 | 0.039 | 0.05 | 0.060 | 0.07 | 0.088 | 0.102 |

| Finish |

Vc

m/min | fz(mm/Tooth) |

| Diameter |

| 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| 332 | 0.028 | 0.05 | 0.07 | 0.091 | 0.11 | 0.128 | 0.144 | 0.16 | 0.173 | 0.186 |

| 272 | 0.026 | 0.046 | 0.066 | 0.085 | 0.103 | 0.12 | 0.135 | 0.15 | 0.162 | 0.173 |

| 304 | 0.028 | 0.05 | 0.07 | 0.091 | 0.11 | 0.128 | 0.144 | 0.16 | 0.173 | 0.186 |

| 212 | 0.023 | 0.041 | 0.059 | 0.076 | 0.092 | 0.107 | 0.121 | 0.134 | 0.145 | 0.155 |

| 196 | 0.027 | 0.047 | 0.067 | 0.086 | 0.104 | 0.122 | 0.137 | 0.152 | 0.165 | 0.177 |

| 168 | 0.024 | 0.043 | 0.061 | 0.079 | 0.095 | 0.111 | 0.125 | 0.139 | 0.150 | 0.161 |

Note OF Micro Diameter Ball Endmill

- If the following carbide micro diameter flat milling cutter cannot meet your requirements, we support OEM customized production. The diameter of 0.2mm to 25mm, the total length of 50mm to 200mm,

4F, 5F, 6F, 8F and logo can be customized, including inch size end

milling cutter. Please contact us to select or customize

non-standard carbide end mill according to your needs.

| flute diameter | flute length | Shank Dia | overall length |

| 0.1 | 0.2 | 4 | 50 |

| 0.15 | 0.3 | 4 | 50 |

| 0.2 | 0.4 | 4 | 50 |

| 0.25 | 0.5 | 4 | 50 |

| 0.3 | 0.6 | 4 | 50 |

| 0.35 | 0.7 | 4 | 50 |

| 0.4 | 0.8 | 4 | 50 |

| 0.5 | 1 | 4 | 50 |

| 0.6 | 1.2 | 4 | 50 |

| 0.7 | 1.4 | 4 | 50 |

| 0.8 | 1.6 | 4 | 50 |

| 0.9 | 1.9 | 4 | 50 |

| R0.1 | 0.4 | 4 | 50 |

| R0.15 | 0.6 | 4 | 50 |

| R0.2 | 0.8 | 4 | 50 |

| R0.25 | 1 | 4 | 50 |

| R0.3 | 1.2 | 4 | 50 |

| R0.35 | 1.4 | 4 | 50 |

| R0.4 | 1.6 | 4 | 50 |

| R0.45 | 1.8 | 4 | 50 |

Instructions OF Micro Diameter Ball Endmill

1. Use high-precision and high opening equipment and fixtures.

2. When the installation rigidity of machine tools and workpieces

is poor, vibrations and abnormal sounds may occur,

At this point, the speed and feed speed in the table below should

be reduced year-on-year.

3. Use air oxygen cooling or MOL (minimum oil cooling).

4. The side is just pushed away and processed in a straight manner.

5. Try to keep the cutting tool as short as possible under non

drying images.

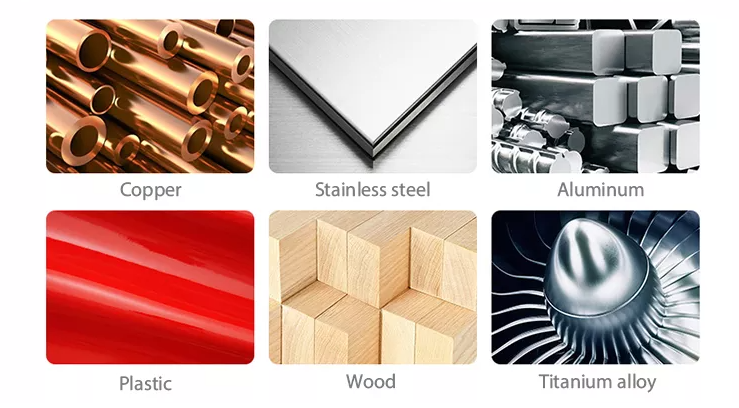

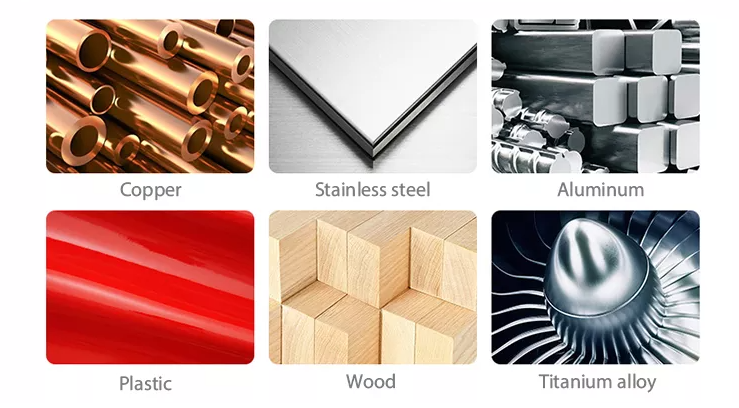

Applications OF Micro Diameter Ball Endmill

The cutting edge of the HRC55 micro diameter square cutter is covered with a bronze colored nano coating, suitable for materials within HRC55, including iron, carbon steel,

cast iron, mold steel, alloy steel, tool steel, heat treated steel,

and welding repair steel

Q1. The tool breaks when cutting in or pulling out the workpiece

The feed rate and cutting depth can be reduced, and the cutting

edge length can be shortened to the minimum of the necessary

length.

Q2. Tool breaks during normal machining

Reduce the feed rate and cutting depth.

The tool shall be passivated.

Replace the clamp or spring collet.

The tool with high cutting edge number changes the tool with low

cutting edge number to improve chip removal and prevent chip

blockage.

Replace dry milling with wet milling (using cutting fluid), and use

it with vortex tube gun to reduce tool temperature and avoid tool

overheating.

If the wet milling fluid supply direction is changed from the front

to the oblique rear or transverse top, the coolant flow should be

sufficient.

Q3. The tool breaks when the feed direction changes

(1) Use arc interpolation (NC machine tool), or temporarily stop

(temporarily) feeding.

(2) Reduce (decrease) the feed before and after the direction

change.

(3) Replace the clamp or spring collet.

Q4. Problem: Part of the blade tip breaks

Chamfer the corners with manual grinding.

Change down milling to up milling.