Q1. The tool breaks when cutting in or pulling out the workpiece

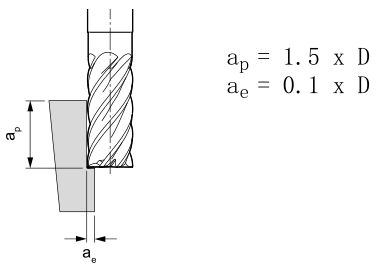

The feed rate and cutting depth can be reduced, and the cutting

edge length can be shortened to the minimum of the necessary

length.

Q2. Tool breaks during normal machining

Reduce the feed rate and cutting depth.

The tool shall be passivated.

Replace the clamp or spring collet.

The tool with high cutting edge number changes the tool with low

cutting edge number to improve chip removal and prevent chip

blockage.

Replace dry milling with wet milling (using cutting fluid), and use

it with vortex tube gun to reduce tool temperature and avoid tool

overheating.

If the wet milling fluid supply direction is changed from the front

to the oblique rear or transverse top, the coolant flow should be

sufficient.

Q3. The tool breaks when the feed direction changes

(1) Use arc interpolation (NC machine tool), or temporarily stop

(temporarily) feeding.

(2) Reduce (decrease) the feed before and after the direction

change.

(3) Replace the clamp or spring collet.

Q4. Problem: Part of the blade tip breaks

Chamfer the corners with manual grinding.

Change down milling to up milling.